Log in to save this article and keep your favorite resources in one place.

The Internet of Things (IoT) and its components have been pushed through a rapid cycle of kindergarten-stage development before going through adolescence. That’s when the IT industry realized that most devices (and indeed platforms) had been developed with little regard for security and enterprise scalability.

As we enter the teenage IoT years, how will the devices and software platforms that we create now evolve further? Specifically, when we look at the cutting edge of “edge computing,” how will digital twin technology continue to transform this technology category?

Digital Twins Defined

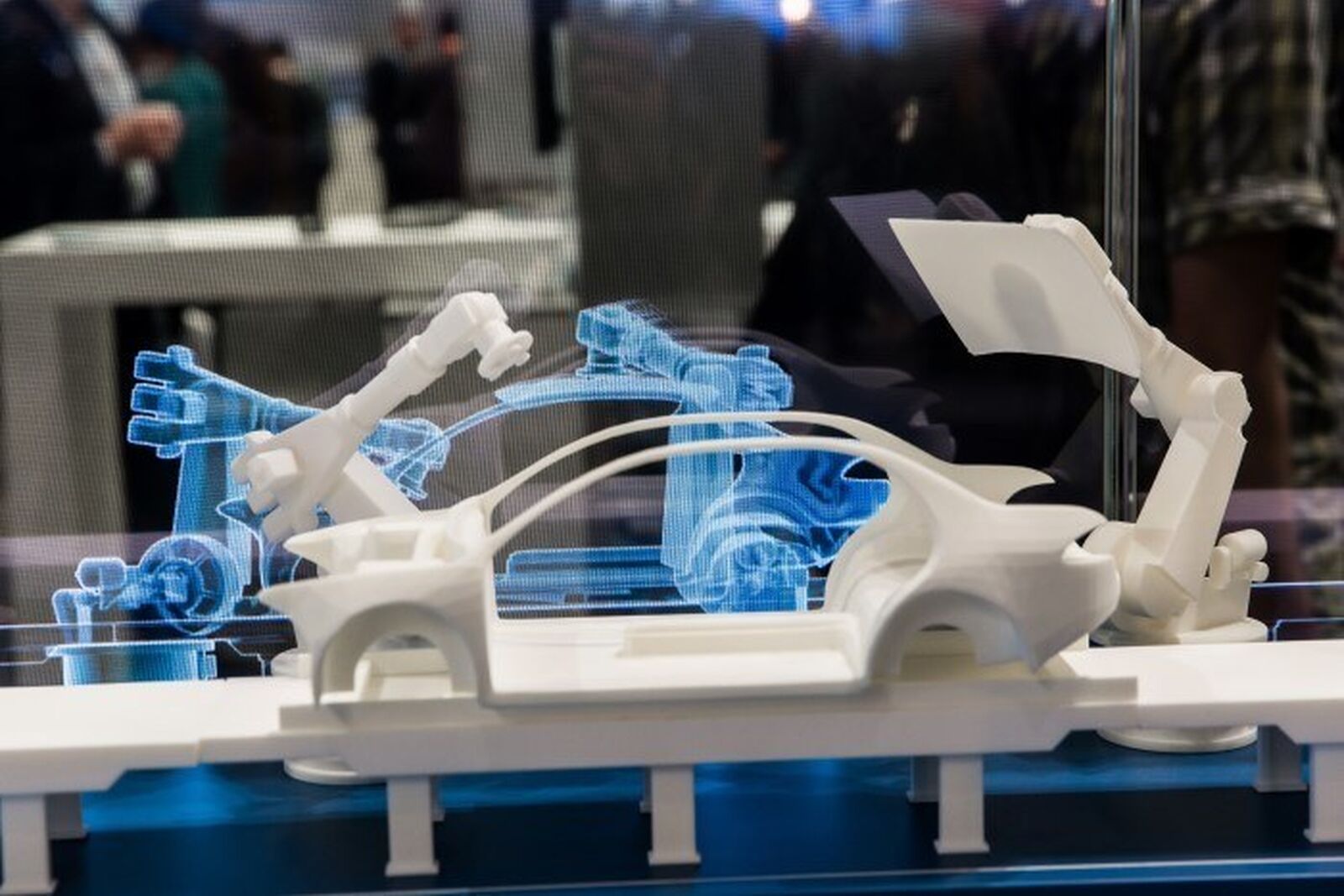

Digital twins are a method for building data-rich models of everything from airplane turbines to escalators and electronic door handles.

These software-based representations of real-world objects (or some form of mechanized or procedural system) are designed to model the exact behavior of their real-world twins to provide a platform for analysis. That analysis allows us to perform predictive maintenance tests, experiment with new tasks, and even apply new levels of artificial intelligence (AI) to the way we execute operations in the real-world system.

Gartner estimates that by 2020 there will be more than 20 billion connected sensors and endpoints. That means digital twins could exist for potentially billions of things in the IoT universe. So, what does this mean for ASUG members?

The Road to Industry 4.0

Initially, ASUG members may look to SAP Predictive Engineering Insights on their road to the so-called Industry 4.0 era where digital twins will allow us to predict and improve asset performance and reliability. Let’s also remember that SAP Leonardo cut its teeth as an IoT platform, so this area of engineering (real-world physical engineering and software engineering) is very much embedded in SAP’s plans for enterprise information management and enterprise asset management.

As for the immediate future of digital twins, what happens next?

Digital Twins in Their Teenage Years

The next shift in IoT platform technologies could see an increased degree of the democratization of information. For example, the insights coming from digital twin systems could be shared with not just the engineering and product development departments, but also the sales and marketing teams.

If the commercial function’s sales and marketing teams start to get access to digital twin information, they can potentially use it in two ways:

- To more directly perform predictive maintenance tests on the equipment that they themselves use.

- To use insights coming from customers to enhance the sales process itself. In other words, if a salesperson knows more about how real-world products perform, that person will be better informed to advise customers on what to buy that best suits their needs.

Packaged Automation

We can also expect more bundles of features in digital twin territory, such as industry-specific and task-specific packages of software that will apply to use cases for automated development functions. In this area, SAP Leonardo IoT Accelerator Packages already exist, as we have covered in the past. As these packages develop and offer a wider range of preconfigured, ready-to-use functionality delivered as a service, we can expect more specific digital twin flavors to emerge from the mix.

SAP will tell us that the use of these technologies, “Enables digital transformation of [insert your industry vertical here] companies so they can become real-time margin-driven businesses.” Whether or not those packages will address the core needs of each industry will remain to be seen. If SAP does offer a specific package for your industry, it may be a good place to start evaluating how it could offer shortcuts for bringing advanced technologies like digital twin into your transformation plans.

Power Up, Then Orchestrate

Let’s also highlight two other key growth areas for digital twins. The first area is for those who want to power up and start using digital twins. These organizations will need to think about the need for rapid bidirectional communication between a digital twin and the actual physical equipment in real-world simulations.

Second, as a direct result of powering these digital twins up, we will need to look at the responsibility for orchestration. As ASUG members grow their own IoT networks, a spider’s web of interconnected information streams will start to develop. To not overwhelm your systems with digital twin IoT data that ends up getting dumped into a data lake, companies will need to prepare a formalized approach to orchestration. SAP Data Hub is one option to help manage this process.

Digital Twins, Finally Going to Work

Organizations will now be able to build new digital supply chains with digital twin insights forming the backbone of this data channel. This is one among other methods now surfacing that show how digital twin technology can be applied to your business model. Sharing more of these use cases and uncovering some areas that ASUG members currently operate with may help inspire more growth in the use of digital twins.

If you’re looking to learn how your peers are doing more with enterprise asset management, you should join us at the SAP-Centric EAM & Supply Chain conference, March 16–18 in San Antonio, Texas. Early-bird registration is available through Feb. 7, and ASUG members receive $200 off registration.

You Might Be Interested In

Log in to save this article and keep your favorite resources in one place.

Log in to save this article and keep your favorite resources in one place.

Log in to save this article and keep your favorite resources in one place.

Log in to save this article and keep your favorite resources in one place.